TAKE YOUR BUSINESS TO NEW HEIGHTS

Achieve continues improvement in Processes, System, Business & Your Desired Organisational Goals!

Fastest Delivery – No hidden Fee – Cost Effective – 3 Years Validity

ISO 13485:2016 Medical devices – Quality management systems

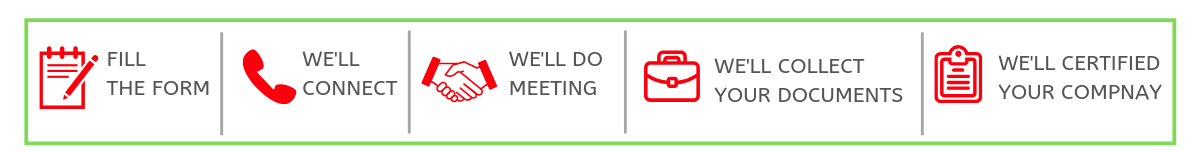

Here, How your Company will Get ISO Certification!

____________

Once your company becomes iso certified your business generally becomes more efficient and productive, giving you an edge over your competitors. You can also enjoy marketing benefits from ISO certification because you can reassure customers that your business follows the highest quality standards.

FAQ

Most frequently asked questions about ISO 13485 Certification and answers

What is ISO 13485?

ISO 13485:2016 accreditation was established by ISO (International Organization for Standardization) and revised in the year 2016 to authenticate Quality Management System and security in medical devices. The medical field is witnessing a continuous development in its technologies and equipment. It is also important for the world to secure safety measures for it.

ISO 13485can be applied by any size of medical service provider throughout the life- cycle of the device. It is entitled in every stage of device life, from planning, production, supply, distribution, storage, installation, controlling, monitoring, maintain and even for post-production. It is not obligatory but still a necessity for medical service providers to be trusted by consumers, stakeholders and all the parties concerning to them.

ISO 13485 can be adopted by any organization manufacturing medical devices irrespective of its shape, size, age, and geographical location. It is currently implemented by the organization in 21 countries.

ISO have adopted the process approach which follows PDCA act (Plan – Do – Check – Act) cycle which brings in a drive for continued perfection in the process of organization.

What are the Requirements of ISO 13485?

- Define adequate quality of design and development plan for medical devices.

- Identification of Quality management process in medical device production and further process.

- Consider customer’s requirements throughout the process.

- Production of sterile medical devices.

- Proper maintenance, control, and repair of medical devices.

- Review

quality of design and development in medical devices. - Meet documentation requirements fundamental to ISO 13485.

- Safe distribution of medical devices.

- An internal audit of the organization.

ISO

what are the benefits of iso 13485?

- ISO 13485 enables the establishment of the Quality management system in medical device production, maintenance, and lifecycle process.

- Improve the process of production and maintenance of medical devices.

- Enhances effectiveness of medical devices

- Ensures safety in medical devices.

- Reduces operational cost.

- Continuous Improvement in medical devices

- Innate trust in stakeholders and customers

- Validate customer satisfaction and wellbeing.

- Encouragement of staff and employee training in medical service providers.

what are the problems we will face in iso 13485?

- Involvement of too much documentation process could be burdensome for the organizations.

- Lack of adequate knowledge about ISO 13485can cause lack of accreditation by the organization.

- Insufficient knowledge regarding customer requirements creates hurdles in the achievement of the desired results.

- Lack of commitment to establish, implement and maintain ISO 13485 based quality management system, results in non-achievement of desired results.

- Adopting a bureaucratic and incompatible ISO 13485

system can prove painful, redundant and build fear in employs which can degrade their motivation. - Organizations may be trying their best, but still failing to reap the results. What they aren’t aware of is that they may not be having adequate resources with them or appropriate management solutions.

- Auditing, Training and improving quality can cost you more than you can input, which makes most of the organization to step out of the process.

- Unprofessional and incorrect offers given by Consultants, that displays a very wide range of pricing. This creates confusion and hampers the Consultant selection process.

- The possibility that the Consultant guides through, and emphasizes on massive documentation which the organization cannot handle, and somehow isn’t the mandatory requirement of the international standard too.

How Oxygen will help you to get iso 13485?

- Oxygen Group experts guide you through proper documentation process of ISO 13485without adding the burden of unnecessary documents on your organization.

- Oxygen Group provides complete understanding and proper training for personnel regarding the quality of the medical device that can solve quality issues easily. Oxygen Group provides training based on the need of the organization and not unnecessary ones.

- Oxygen Group helps through imparting the right education regarding coordination and motivation of management and employees help you achieve ISO 13485 standard

- Oxygen Group provides required training, education and confidence to employees thus making QMS a regular habit for them which eradicates fear and dopes confidence.

- Oxygen Group experts guide you about the inadequate resources that will resolve various problems in the failure of ISO 13485 conformity.

- The Oxygen Group Solutions Architect guides you through the entire ISO 13485

compliance and implementation till achievement of certification which will give you a sigh of relief. - Oxygen Group facilitates in-depth and professional auditing services that are significantly more stringent than the audits done by certification bodies. This ensures no failure during external audits.

- Oxygen Group works 24X7, to cater to the needs of its customers all over the world. This gives you ample opportunity to demand our services even in

the odd hours and holidays. - Oxygen Group has a general practice of complete analysis before an offer is given. It is extremely improbable that the total expenditure goes beyond the budgeted figures unless there are special requirements from the client’s end. “Not a single penny extra”, is a general motto that each Oxygen Group employee abides by.